When you’re hauling van trailers, you could be hauling any number of things. Is it cheesy holiday decorations for the TJ Maxx up the road? Is it furniture in a million tiny pieces designed to be put together with instructions that never quite make sense? Or maybe you’re hauling boxes and boxes of food.

Regardless of what you’re hauling in the back of your van trailer, you need to know how much it weighs. Can you receive a citation for hauling horrendously ugly clothing or decorations? Probably not. But can you get a citation for being overweight? Absolutely.

And I can guarantee you that if you’re pulled over and caught being over legal weight limits, you’re not going to get off with a slap on the wrist. You’re definitely going to be getting fined. Why? Hauling overweight cargo can damage the roads. (More on that below.)

Despite all the tools you have as a truck driver, drivers still receive these overweight citations every day. That’s why I’m going to give you some easy tips to help you adjust your trailer so that you don’t ever have to get hit with a hefty fine for hauling an overweight load.

Before I began working as a safety manager at Anderson Trucking Service (ATS), I was a truck driver for more than a decade. I’ll help you understand the tips and tricks I followed to succeed out on the road and the tips and tricks that I teach ATS drivers every week.

Keep reading to learn about why weight limits are important in the first place and tips for making sure the weight of your van and reefer loads are properly distributed.

Why Are There Weight Limits on Van Trailers and Reefers?

Until you became a truck driver, you probably never thought about the weight of your vehicle. Why does it even matter, right? Unless you’re going over a bridge, the roads should be sturdy enough to support however much weight you’re hauling, right?

Wrong.

Our roadways can only handle so much. When vehicles exceeding those limits pass over those same roadways, they can compromise the structure of the road and do some serious damage. Bridges and overpasses are especially susceptible to damage because they have weaker spots in their structure. Vehicle weight should not exceed the weight of the weakest point of the roadway.

Every state has its own little intricacies and rules, but for the most part, commercial motor vehicles are allowed a maximum legal weight of 80,000 with 12,000 pounds on the steer tires, 34,000 pounds on the drive tires and 34,000 pounds on the trailer if you have a standard tandem trailer. Your entire vehicle can be overweight, but your trailer can also be overweight on axle groups.

Because you have the potential to significantly damage roadways if you’re overweight, the Department of Transportation (DOT) takes infractions of this rule seriously. Weight-related violations can be costly. If you’re involved in an accident and you’re extremely overweight, you can see big consequences.

If you’re hit with a violation, you could possibly be required to stay at that weigh station until you can get your load to a proper weight. That may mean having pallets removed from your trailer to lower the weight or it could mean adjusting your trailer (tips below) to redistribute the weight.

Either way, you may need to shut down or find a facility to reposition and legalize your load. We all know shutting down means you’re losing money. If you can’t simply redistribute the weight on your trailer, you’ll have to have someone come to assist you. That means more time and more money.

Someone will have to drive to you with a trailer and the equipment required to get freight from your trailer to theirs. The cost of this service may fall to you or your company depending on what kind of company you drive for and what type of driver you are.

In the flatbed world, drivers can get overweight permits because, at times, a single piece of freight the drivers are hauling is overweight. The same permits can’t be arranged for a van load because you can reduce the weight of the load by removing pieces (or pallets or boxes) from the load. Therefore, your load is reducible and freight can be removed until you’re legal. No special permits are needed for you!

7 Tips for Van Weight Distribution

These general tips will help you troubleshoot and adjust your truck and trailer if you happen to be overweight at a scale.

1. Know What the Tractor and Trailer Weigh

For the most part, knowing what your tractor and trailer weigh shouldn’t be too big of a deal for you as a van driver because the trailers don’t vary much like they do as a flatbed driver.

However, if you’re a dry van driver versus a reefer driver, you’ll encounter some significant weight differences. The trailer has to be insulated and the refrigeration equipment carries some weight to it too.

It’s a good idea to know what you weigh at all times — loaded or otherwise.

2. Plan Ahead

As a truck driver, you should always be planning ahead. Just like you should always know what your tractor and trailer weigh, you should always know how much your next load weighs. Then, you’ll know exactly how much fuel you can have in your tank and still be legal.

Great drivers will determine how much their next load weighs and plan out how many gallons of fuel they can legally hold and where they can get it. They’ll also plan where they can fuel as they haul the load to ensure they continue to stay legal.

3. Know Where the Center for Weight Distribution Is

If you need to redistribute your weight, you have to know where your center point is first. Think of your trailer like a seesaw. You have a lighter person on one side and a heavier person on the other. Where does the fulcrum need to be to make it balanced?

Balancing the weight on your trailer uses the same principle. When you adjust your fifth wheel or tandem, you’re adjusting the fulcrum or changing the center for weight distribution. You’re shifting the weight of your cargo forward or backward without ever physically touching the cargo.

You can’t always see how the trailer is loaded, but if you can, take advantage of it. This will give you the opportunity to see if the loading pattern is set up for success or if you’ll need to make adjustments. This also gives you the opportunity to make sure the load is secure. Failing to secure the load can cause damage to the product and can be dangerous for anyone who has to open the doors of the trailer.

4. Adjust the Fifth Wheel

Adjusting the placement of your fifth wheel allows you to shift and redistribute the weight of your cargo. Sliding the fifth wheel one way or the other will either move the weight forward to the steer tires or it’ll move it back toward the drive tires. For instance, if you have more than 12,000 pounds on your steer tires (which would make you overweight), you can slide the fifth wheel backward and remove weight from the steer tires, therefore shifting weight onto the drive tires.

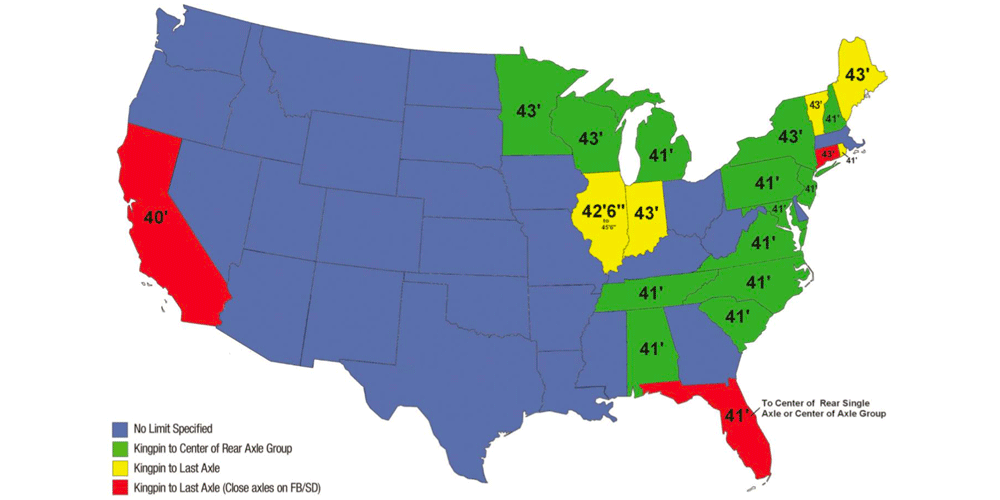

However, when adjusting your fifth wheel, you need to keep the Bridge Formula in mind (see image below). The Bridge Formula dictates how far the kingpin can be from the center of the suspension or the center of the rearmost axle. It was introduced in 1975 to limit the weight-to-length ratio of vehicles crossing bridges. You particularly have to pay attention to this in states like Florida and California and states on the east coast.

5. Slide the Tandems

Just like you can adjust your fifth wheel, you can also slide your tandems to redistribute weight.

When you slide the trailer tandems forward, you take weight off the drive axles and put more weight on the trailer. If you do the opposite and slide the trailer tandems toward the rear of the trailer, you put more weight onto the drive axles.

6. Weigh at a Scale

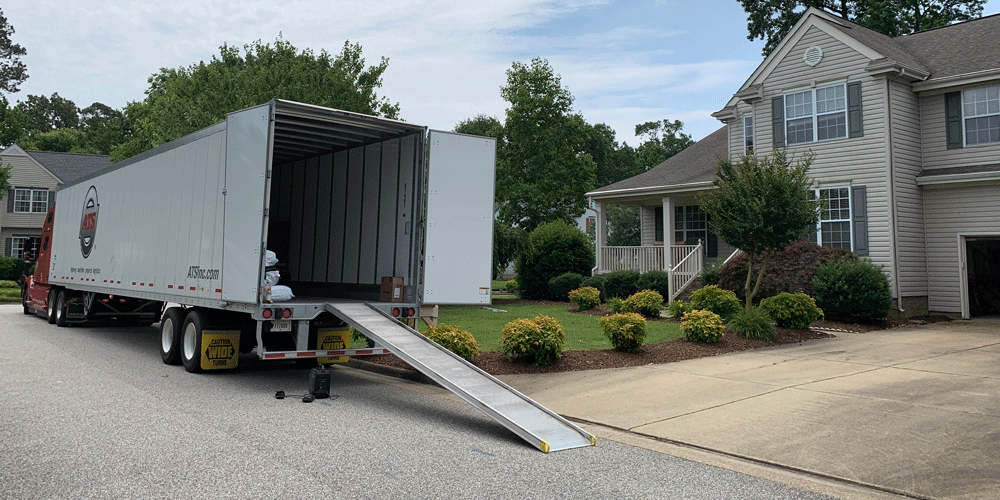

As a van driver, you don’t touch the cargo like a flatbed driver would. You back up, the customer loads you, they tell you you’re done, you pull away, you close the doors and then put the seal on.

Once you do that, your next step should be to find the nearest scale — often at a truck stop — to check the weight of your truck and trailer. This is one of the best ways to ensure you’re not overweight.

It’s far better and easier to find out you’re overweight near a shipper and then turn around and go back to the shipper to have the cargo adjusted than it is to get caught being overweight at a DOT scale. There’s really no excuse for being overweight, ever, so most officers won’t give you a break at a weigh station if you’re in violation.

7. Use Air Scales

Some trucks, but not all, are equipped with air scales. Historically, they’ve been an expensive tool, which is why every carrier might not have them on their trucks. However, we’re seeing prices coming down on them — making them more available. Drivers who are insistent on having an air scale should look to work for a larger carrier where the technology is more common.

With air scales, there’s a pressure gauge on your trailer that utilizes the suspension of your airbags to tell you how much pressure is being applied to the drive tires. They provide a rough estimate of how much the load weighs so you can determine if you’re overweight.

Many drivers heavily rely on these air scales and some even use them instead of going to a scale at a truck stop.

There are some in-cab versions of air scales, too. Technology is developing rapidly. Many air scales can pair with an app on your phone now so you don’t even need to leave the cab.

Avoid Citations and Fines

There’s a reason commercial motor vehicles have weight restrictions. The restrictions are in place to prevent damage to roadways.

With a few simple practices in place, ensure you never receive a citation for hauling a load that’s overweight. Know how much your tractor and trailer weigh before you arrive at the shipper, check your weight using air scales or a nearby scale and adjust your fifth wheel or tandems as needed.

Failing to follow regulations can result in hefty fines and a lot of time lost.